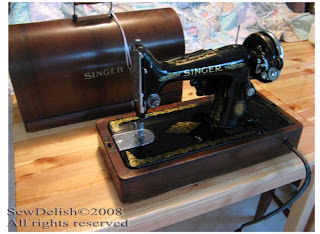

This is my Singer 201K from the 1950’s. When I bought it, it had only been used as a hall table for many years and the machine itself was never used by the owner. The table was in really good condition and clearly had been polished regularly. The machine however needed cleaning and the power lead, pictured below, needed replacing. Thankfully after a good clean and service I ended up with a great working machine. This tutorial came about because I could not find much information on cleaning these old sewing machines. Here I will share with you how I clean my machines, no matter how old they are.

Things

you will need:

- Newspaper - to sit your machine on and protect the surface underneath

- Rags - lots for cleaning and polishing

- Paper towels to sit cleaned items to dry

- Toothbrush or paintbrush - to clean stubborn areas

- Cotton tips

- Vacuum cleaner with a Computer attachment (it allows you to reach small areas easily)

- Kerosene

- brass or silver cleaner

- good quality sewing machine oil

- gloves to protect your hands from the dirt and chemicals

- notepad and pencil or digital camera to make notes as you take things apart

How I Clean My Old Machines:

Remember

to only do one section of your machine

at a time to make it easier to put back together!!!It can

help to take photos or takes notes as you work. If you have a manual for your

machine keep it handy, just in case you need to refer to it.

|

| Computer Attachment for Cleaning Sewing Machines |

|

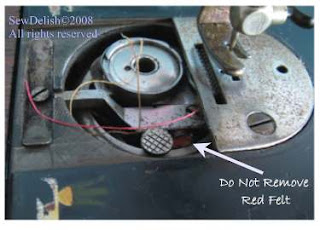

| Do Not Remove any Red Felt you find |

- Remove the needle from the machine as this makes cleaning easier and safer. Remove and the shiny parts and clean with brass or silver cleaner. I was told by my local sewing machine repairer that brass cleaner is much softer on the metal parts and will cause less scratches and wear in the long term.

- Remove lint from the bobbin case and under the machine. I use my vacuum cleaner with a tiny computer nozzle attached to make it easier. Some people use canned air but I don’t like the dust blowing around getting into places that may cause damage later. I prefer to get rid of it completely with the vacuum. NOTE: If you find something that looks like a piece of red felt, LEAVE IT THERE! It is felt and helps to lubricate things. It is meant to be kept oiled. Do not take it out. The model in the photo below is a Singer 66-1

- Clean areas under the faceplate and underneath with some kerosene on a rag, paintbrush or cotton tip. This is also safe to use on decals but I would be careful on worn areas anyway to help preserve them. Don’t forget the feed teeth. Wipe away any excess.

- Oil the machine on all the moving parts where metal touches metal. It also helps to refer to the manual if you have one for your model. You can find out the model number of your machine at ISMACS using the serial number which is found on the front base plate of the machine. This site will also tell you approximately when your machine was manufactured.

- Replace all removed parts. Worn bobbin winder tires and belts should be replaced with new ones, especially if you intend to use the machine. Keep the originals.

- Once you have finished cleaning, the whole machine can then be given a polish with some machine oil or a wax and polish with a gentle car wax. I just used sewing machine oil as I didn't have any car polish. Just be careful over the decals. Do not allow any oil to come into contact with the rubber bobbin winder tyre or belt. This will cause them to perish quicker, and will make them slip if you intend to use the machine.

- Any gears on the machine will need to be greased. I use grease from my local sewing machine repair shop. Follow your manual for application points as grease should NEVER be used like sewing machine oil and the oil should NEVER be used in place of grease

- Inspect any electrical wires and cords if your machine has them. Damaged ones should be repaired or replaced by a licensed electrician. A power cord that looks like this really needs replacing, even if it does work! This one has perished from being in the same coiled up position for years. I usually give this job to an electrician.

- Polish the wooden table or bentwood cover if you have one with a quality wood polish. I used marveer.

More information can be found here my post on Helpful Links on Antique and Vintage Sewing Machines, ISMACS and Treadleon.

If you find this information useful or something is not quite clear, please feel free to leave a comment.

***My Original blog post on this topic has been now been restored and can be found here. *****